Overview

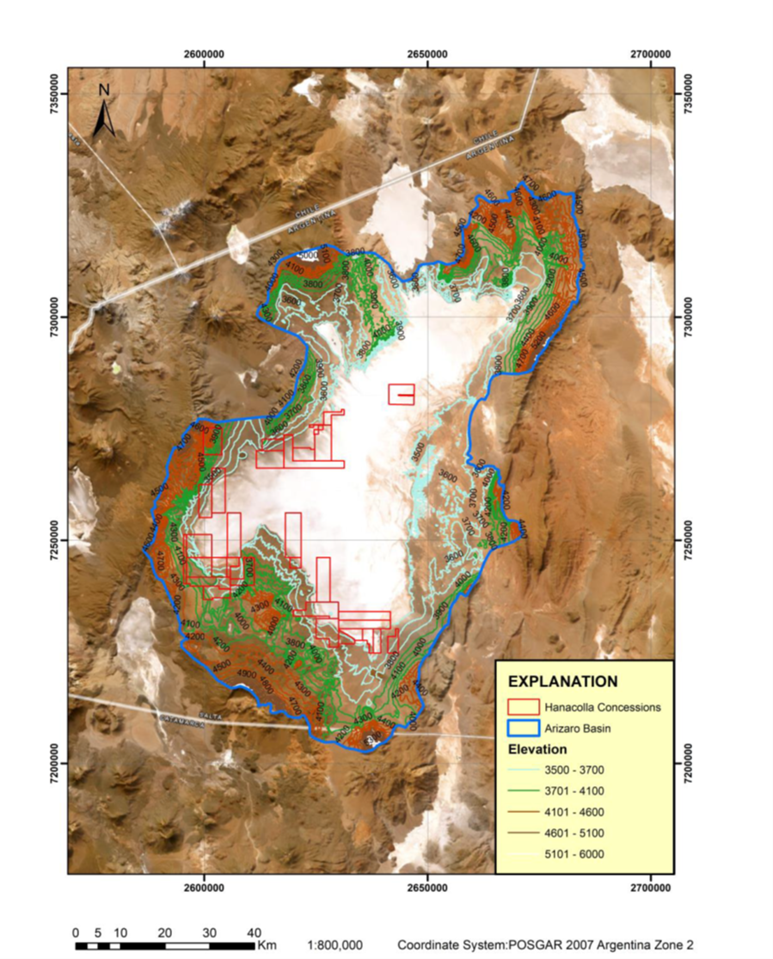

The Doncella project is a lithium in brine project, with an area of 62,507 hectares, located in the Arizaro salt flat in Salta province, northwest Argentina.

Exploration Stage

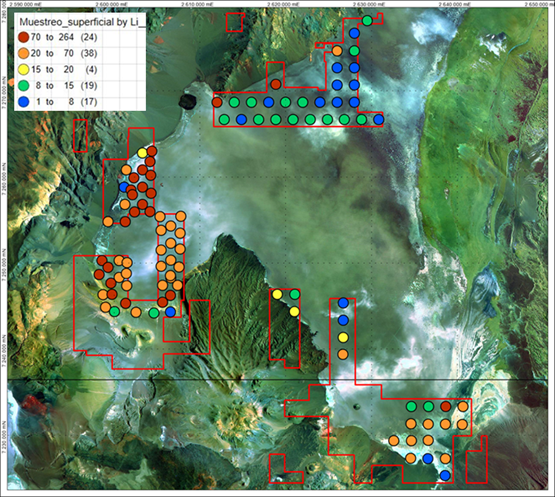

Hanacolla S.A. launched the exploration program in May 2018, identifying key areas of interest.

Trench Sampling:

Several trenches were excavated, reaching depths of up to 3.20 m.

A total of 112 trenches were excavated in a regular grid pattern.

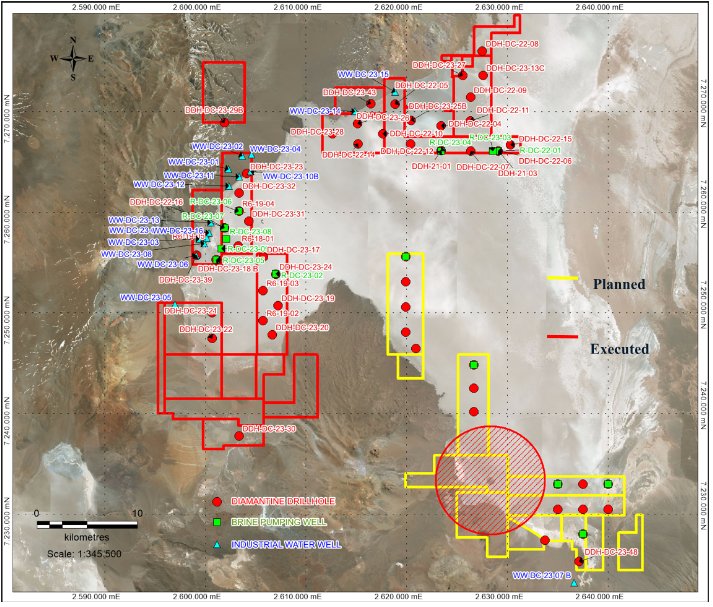

Drilling commenced in 2019 and paused temporarily due to the 2020 pandemic.

In summary, as of today we have carried out:

- 45 diamond drill holes (DDH),

- 12 rotary wells (R),

- 19 water wells.

- 20 piezometric Wells.

These efforts formed the basis for the NI 43-101 Technical Report, finalized in January 2024 by Montgomery & Associates.

Which have been successfully drilled in two drilling campaigns, in 2019 and 2023, with more than 10 thousand meters of diamond drilling and 2900 meters of rotary drilling and 1700 meters of rotary well water.

In addition, 584 meters of monitoring wells for water.

Total Estimated Resources for the Doncella Project (Effective Date of December, 2023)

| Resource Category | Brine Volume (m3) | Avg. Li (mg/L) | In situ Li (tonnes) | Li2CO3 Equivalent (tonnes) |

| Measured | 1.6E+09 | 167 | 265,000 | 1,410,000 |

| Indicated | 1.2E+09 | 161 | 192,000 | 1,023,000 |

| Measured + Indicated | 2.8E+09 | 164 | 457,000 | 2,433,000 |

| Inferred | 1.0E+09 | 173 | 176,000 | 940,000 |

| Total Resource | 3.400.000 |

Brine infiltration study

The project contemplates the discharge of depleted brines (DSA) from the Lithium Carbonate Process Plant on the natural topographic surface of the land due to the effect of infiltration. The chosen area has an infiltration capacity of 95% for a flow of 164 l/s, and a lagoon of 12ha throughout the exploitation.

DLE Process

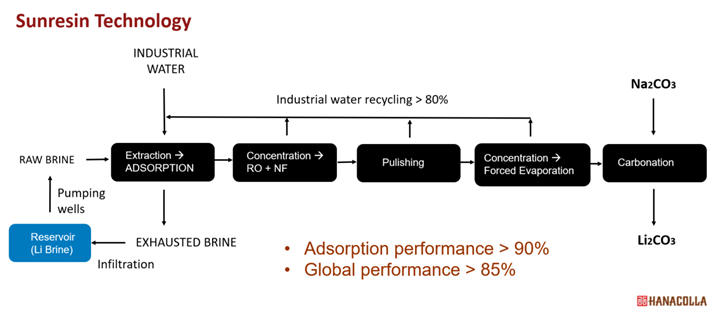

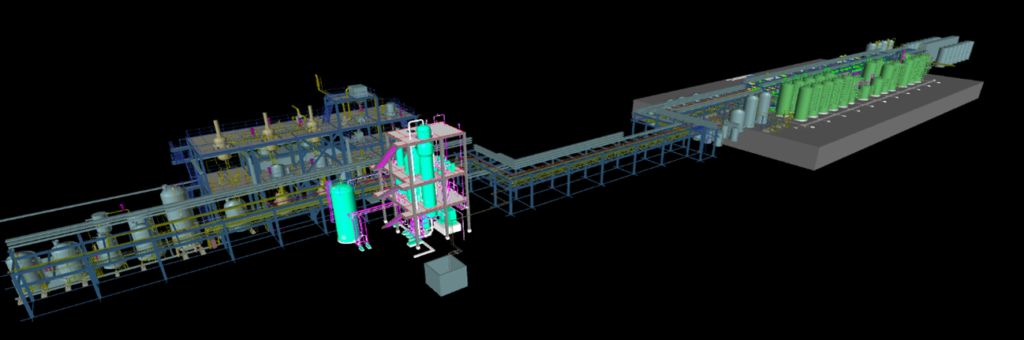

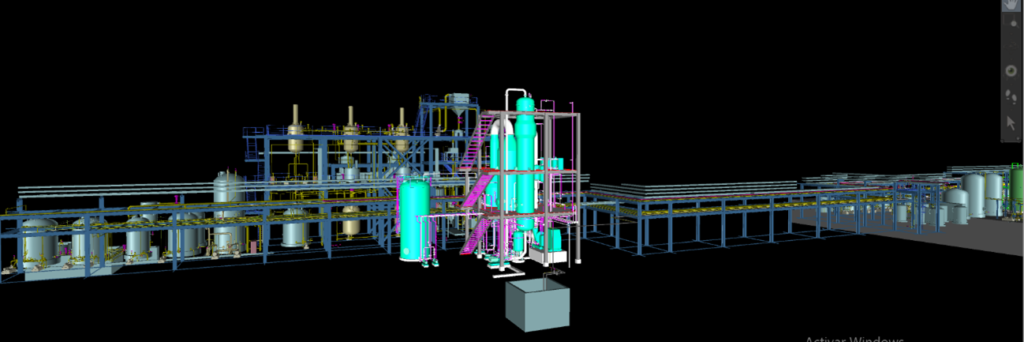

In parallel, Hanacolla partnered with the Chinese DLE expert Sunresin New Materials Co. Ltd., in July 2023 to deploy Direct Lithium Extraction (DLE) technology through a turnkey pilot plant with a production capacity of 3,000 tons per annum of battery-grade lithium carbonate.

We can mention that in addition to the high efficiencies obtained, the consumption of acid and hydroxide in the cleaning stages are lower than the conventional method. Considering sodium carbonate (ash soda) as a significant reactant.

Plant fabrication was completed by January 2024, supported by the engineering for local civil works from M3 Engineering and power distribution from Saxum.

These advancements form the backbone of the Definitive Feasibility Study (DFS) for Doncella Phase I, under the consultancy of Ad-Infinitum and Montgomery & Associates, both signatory Qualified Persons (QPs).

The project has also finalized the expansion of the construction of the camp facilities, which will support the construction phase starting in Q1 2025.

In addition, Doncella Project has reached a key milestone by obtaining the Environmental Impact Statement (EIS) for the construction and operation of its lithium carbonate plant.

This achievement was made possible after the successful completion of the Free, Prior, and Informed Consultation process, along with the Public Hearing held in the community of Tolar Grande. These steps represent a significant advancement in our commitment to responsible mining and sustainable development in the region.

Currently our camp has the necessary services for the work team that carries out its daily activities.

Expansion phase

Hanacolla initiates Pre-Feasibility Studies to Increase Production of Battery-Grade Lithium Carbonate.

It will have a production capacity of 22Kton/y , that, added to the initial 3000ton/y, will have a total production of 25Kton/y.

having as a construction horizon Q1 2027 and start-up Q1 2028.